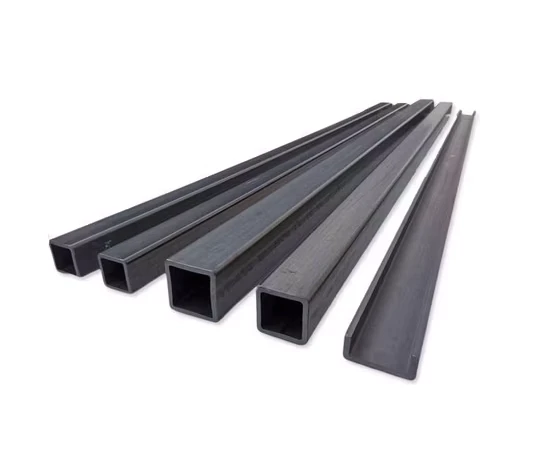

Silicon carbide beam is made of quality silicon carbide material. It features excellent oxidation resistance, high temperature resistance, and long service life. Many high-temperature industrial furnaces use this product for industrial load-bearing support.

Specifications Of Silicon Carbide Beam for Sale

| Item | Index | |

|---|---|---|

| SIC Chemical Composition, % | ≥ | 90 |

| Max.Service Temp, °C | 1400 | |

| Refractoriness, SK | ≥ | 39 |

| 2kg/cm² Refractoriness Under Load, kg/cm² | ≥ | 1650 |

| Modulus of Rupture at Room Temp, kg/cm² | ≥ | 500 |

| Modulus of Rupture at 1400°C, kg/cm² | ≥ | 100 |

| Compressive Strength, % | ≥ | 1300 |

| Thermal Expansion at 1000°C , % | 0.42 -0.48 | |

| Apparent Porosity, % | 7-8 | |

| Bulk Density, g/cm² | 2.70 -2.75 | |

| Thermal Conductvity at 1000°C, kcal/m.hr. °C | 13.5-14.5 | |

Sizes Of Kerui SIC Beams

Kerui offers silicon carbide beam in various custom cross-sectional sizes and wall thicknesses to meet specific customer requirements. Send your details to us.

Advantages of Silicon Carbide Beams

Excellent High-Temperature Performance: siliconized SiC beams possess an extremely high melting point, allowing them to be used for prolonged periods at elevated temperatures without degradation.

High Strength: These non stick kiln shelves exhibit impressive bending and compressive strength, ensuring stable performance in environments with significant mechanical loads.

Good Oxidation Resistance: The surface of the beams remains stable even at high temperatures, providing reliable performance in demanding conditions.

Good Thermal Stability: With excellent thermal shock resistance, RBSIC beams maintain stability during rapid temperature changes, ensuring consistent performance.

High Thermal Conductivity: The beams allow for quick dissipation of heat, facilitating efficient heat transfer during the firing process.

Applications of SISIC Beams

Silicon carbide beams primarily serve functions such as support, transport, and insulation in industrial kilns.They are mainly used in ceramic kilns, thermocouple protection components, supporting ceramic products, and ceramic sintering kilns, as well as in the metallurgy, electronics, and chemical industries.